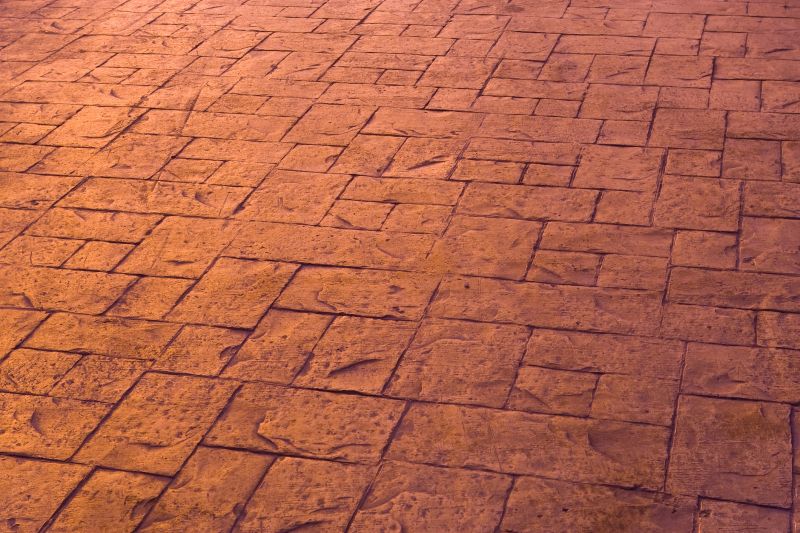

Concrete Polishing for Durable Surfaces

Concrete polishings are a durable flooring solution that enhances the appearance and longevity of concrete surfaces. They involve grinding and polishing concrete to achieve a smooth, glossy finish that resists wear and stains. This process is suitable for commercial, industrial, and residential applications, providing a low-maintenance and aesthetically appealing surface.

Concrete polishings should be performed when ambient temperatures are between 50°F and 85°F with low humidity to ensure proper curing and adhesion.

The concrete surface must be fully cured and free of moisture issues, typically requiring a curing period of at least 28 days after pouring.

Scheduling during periods of low activity minimizes disruptions and allows for proper curing and finishing processes.

Spring and early fall are ideal seasons due to moderate weather, reducing risks of temperature fluctuations that can affect the polishing process.

Preparation is key to ensure optimal results in concrete polishings.

Advanced equipment ensures a high-quality finish.

A glossy, durable surface ready for use.

Ways to make Concrete Polishings work in tight or awkward layouts.

Popular materials for Concrete Polishings and why they hold up over time.

Simple add-ons that improve Concrete Polishings without blowing the budget.

| Factor | Recommended Timing |

|---|---|

| Temperature | 50°F to 85°F |

| Humidity | Low humidity levels |

| Concrete Cure Time | Minimum 28 days after pouring |

| Season | Spring or early fall |

| Surface Readiness | Fully cured and dry |

Concrete polishings improve surface durability, enhance aesthetic appeal, and reduce maintenance costs. The process involves multiple stages, including grinding, honing, and polishing, to achieve the desired finish. Proper timing ensures optimal adhesion and surface integrity, resulting in a long-lasting, high-quality floor.

A high-gloss, smooth finish enhances visual appeal.

Specialized tools used for surface preparation.

Durable flooring suitable for heavy use.

Aesthetic and functional flooring solution.

High-end options that actually feel worth it for Concrete Polishings.

Finishes and colors that play nicely with Concrete Polishings.

Little measurements that prevent headaches on Concrete Polishings day.

A 60-second routine that keeps Concrete Polishings looking new.

A frequent mistake in Concrete Polishings and how to dodge it.

Small tweaks to make Concrete Polishings safer and easier to use.

Lower-waste or water-saving choices for Concrete Polishings.

The short, realistic tool list for quality Concrete Polishings.

Scheduling concrete polishings during optimal weather conditions and after proper surface curing can significantly impact the quality and longevity of the finish. Proper planning ensures the surface is ready for polishing without delays caused by environmental factors or moisture issues.

Interested in concrete polishings? Fill out the contact form to discuss timing and requirements.